Description

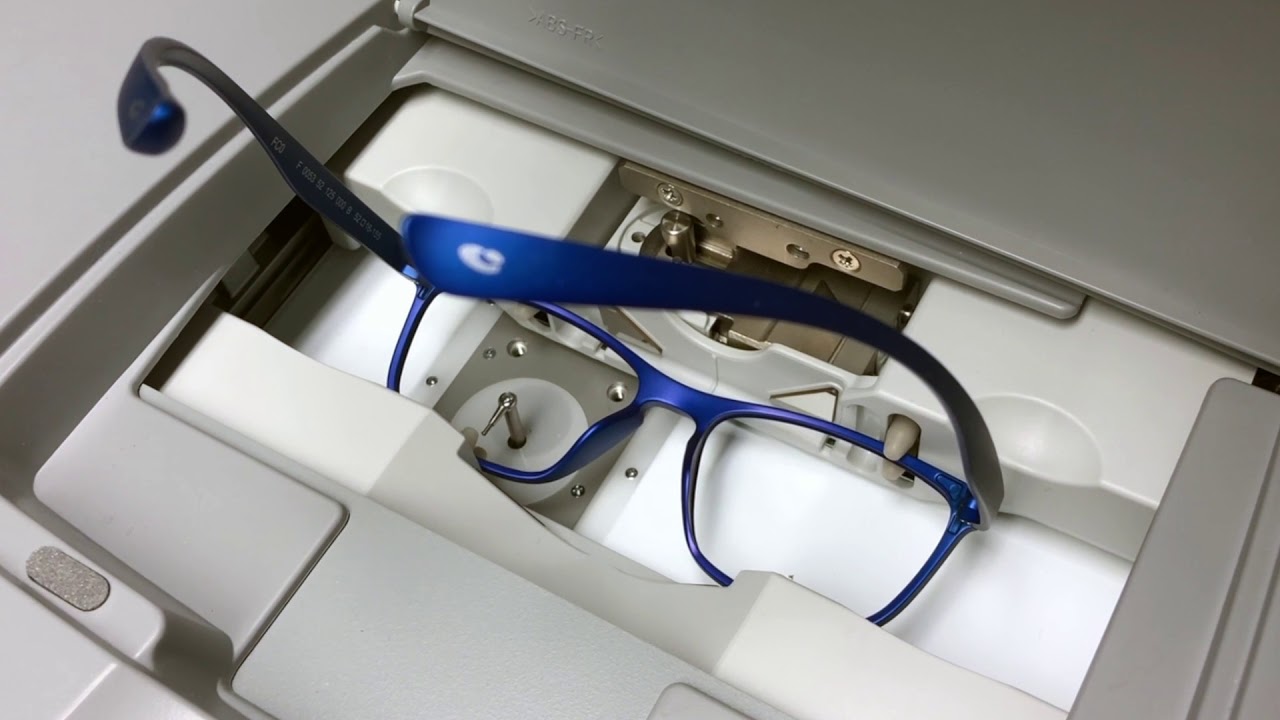

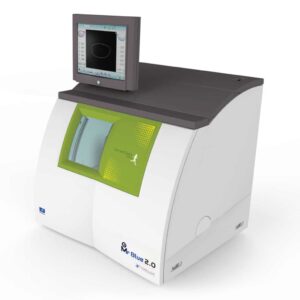

Nidek LE 1200 offers faster-grinding capabilities. Short cycle time and high-luster finish are the results of the latest design improvements. A tailored mini bevel is ideal for thin metal eyewire frames, for example, aviator-style metal frames. Fully-automatic grooving and safety beveling is performed smoothly with a unique “multi-disk” arm. Specially designed wheels provide highly accurate grooving and safety beveling. With the LE-1200, even high base curve lenses attain a beautiful finish.

The NIDEK patternless edger LE series was born from the trusted, symbolic relationship with optical professionals and quickly became the industry favorite. From the very first model, the core spirit of the LE series has blossomed through the years and is now a sought-after standard.

Achieving 15% faster processing compared to conventional models and equipped with a new tracer to accommodate a wide range of frames, the LE series is now reborn with new and refreshing technology in a grey color body.

Nidek LE 1200 Features:

- Heavy-duty, durable mechanisms

Direct drive stepping motor and sintered-gear system provides a steady and reliable operation. Y-axis assembly with unique design delivers consistently high precision.

- Chuck pressure stabilizer

Lens chucking assembly secures the lens with an appropriate, continuous, and stable pressure for grinding.

- Shorter cycle time

The LE-1200 offers faster grinding capabilities. Short cycle time and high-luster finish are the results of the latest design improvements.

- Advanced soft grinding mode

A gentler processing mode keeps hydrophobic coated lenses perfectly on the axis.

- Polish mode

Lens edge polish is available for flat and bevel lenses.

- Grooving & safety bevelling

Fully-automatic grooving and safety bevelling is performed smoothly with a unique “multi-disk” arm. Specially designed wheels provide highly accurate grooving and safety bevelling. With the LE-1200, even high base curve lenses attain a beautiful finish.

- Mini bevel

A tailored mini bevel is ideal for thin metal eye wireframes, for example, aviator-style metal frames. The LE-1200’s redesigned software adds a tailored “mini bevel” function at the push of a button, providing a custom-fit lens for thin, metal eyewire frames, such as Ray Ban™ aviator style. As a result, the cosmetic appearance of the finished eyewear is greatly enhanced.

- New multiple-frame tracer

The new tracer accurately measures various frames, including high-wrap style. The unit’s onboard tracer offers heightened shape detection and size measurement accuracy for multiple structures, including sports styles. Lens and pattern tracing has never been easier with the magnetic-mounted pattern setting assembly and simple, one-touch operation.

- New Software

Additionally, the new software senses the lens blank diameter. Together with lens measurement data and the lens material, it automatically selects the most-efficient lens processing method and cycle time. Therefore, even today’s super hydrophobic coated lenses can be edged without axis shifting.

- Simple “one-touch” demo lens tracing

Easy-load, magnetic pattern setting assembly provides single-step tracing operation.

- Integrated air duct for deodorization

- Color-coded alert-LED for lens identification

- Easy Shape Editor

Customized shapes can be created effortlessly with the Shape Editor screen. Changing the height of drill mount frames makes progressive lens layout much easier with this function.

Technical Data:

Grinding system Patternless

Mode Beveling (automatic, guided)

Flat edging (polishing, safety beveling, grooving)*1

Mini beveling (0.4 to 0.7 mm) (0.1 mm increments)

Setting range

FPD 30.00 to 99.50 mm (0.50 mm increments)

PD 30.00 to 99.50 mm (0.50 mm increments)

1/2PD 15.00 to 49.75 mm (0.25 mm increments)

Optical center height 0 to ±15.0 mm (0.1 mm increments)

Size adjustment 0 to ±9.95 mm (0.05 mm increments)

Bevel position 0 to ±15.0 mm (0.1 mm increments)

Minimum grinding size

Flat edging ø32.0 x 19.5 mm / with a mini cup (optional) ø22.0 x 17.4 mm

Bevel edging ø33.0 x 21.0 mm / with a mini cup (optional) ø23.0 x 18.4 mm.

Safety beveling (flat) ø34.5 x 21.5 mm / with mini cup (optional) ø24.5 x 19.9 mm

Safety beveling (bevel)*2 ø35.5 x 22.5 mm / with mini cup (optional) ø25.5 x 20.9 mm

Grooving*2 ø32.0 x 19.5 mm / with a mini cup (optional) ø22.0 x 17.4 mm

Tracing unit

Method Automatic 3-D binocular tracing

FPD measurement Available

Frame clamping One-touch automatic clamping

The setting of stylus is Switchable between automatic and semiautomatic

Measuring points 1,000 points

Measurement accuracy Frame tracing ±0.05 mm (circumference error with ø45 standard frame)

Wheel configuration Type PC, PL-4, PLB, PLB-2R

Water supply system Pump circulation or direct connection to tap water

Interface RS-232C – 2 ports

One port for connection with a PC or blocker

One port for connection with a barcode scanner

Power supply AC 100 to 120 V or 230 V

50 / 60 Hz

Power consumption 1.3 kVA

Dimensions / Mass 528 (W) x 493 (D) x 345 (H) mm / 41 kg

20.8 (W) x 19.4 (D) x 14.0 (H)” / 90 lbs.

Standard accessories Pliable cup (red, green),

Pliable cup for high base curve lenses (red, green),

Double-coated adhesive pad, Pliable cup remover,

Dressing stick for glass roughing wheel (type PL-4, PLB-2R, PC),

Dressing stick for finishing wheel,

Compound kit for polishing wheel (type PL-4, PLB, PLB-2R),

Pattern setting unit*3, Standard frame*3, Standard pattern*3,

Stylus cover*3, Frame support attachment*3,

Hexagonal screwdriver (2.5 mm), Hexagonal wrench (2.5, 4 mm),

Adapter set, Spare fuse, Accessory case, Power cord

Optional accessories Specified table, Barcode scanner, Circulation pump, and tank,

Mini cup set, Calibration jig

In conclusion, the Nidek LE 1200 Patternless Lens Edger is an advanced ophthalmic instrument designed to provide accurate, efficient, and convenient lens edging for eyewear. This machine has advanced features like auto-tracing, auto-blocker, and grooving capabilities, ensuring precise and customized edging for every lens. The intuitive interface and easy-to-use controls make it a user-friendly device for optometrists and opticians.

The Nidek LE 1200 is also durable, reliable, and requires minimal maintenance, making it an excellent investment for any eyewear practice.

Overall, the Nidek LE 1200 Patternless Lens Edger is a top-of-the-line product with excellent cost value. It is highly recommended for any eyewear practice looking to improve its lens edging capabilities.

Reviews

There are no reviews yet.