In today’s optical industry, patients demand faster service and flawless results. A recent survey found that 46% of optometrists see rising patient expectations. This shows that efficiency and precision are becoming more important.

Lens finishing systems with High-Volume Production are the backbone of modern optical labs. These tools do important jobs like edging, polishing, beveling, and drilling lenses. They provide steady, high-quality results and make operations easier.

In this guide, you’ll learn:

- How automation enhances productivity and reduces errors

- Features of industry-leading lens finishing systems like the Briot Emotion 2

- Tips for choosing and maintaining the right system for long-term ROI

This guide is for technicians, optometrists, and clinic managers. This will help you choose tools that boost efficiency, accuracy, and patient satisfaction.

What Are Lens Finishing Systems?

Lens finishing systems are essential tools in optical labs. They change raw lenses into ready-to-use products with precision and efficiency. These automated tools streamline workflows, reducing errors and ensuring consistent quality. By replacing manual processes, they empower optical labs to meet modern demands for accuracy and faster turnaround times.

Analysts expect the global market for optical lens edgers to grow by 7% each year. The projection indicates a reach of $812.8 million by 2031. This shows that more people are relying on these important systems.

From Raw Materials to Precision Lenses: The Magic of Lens Finishing Systems

Lens finishing systems simplify the intricate process of creating high-quality lenses. Each stage contributes to achieving precision, functionality, and aesthetic appeal.

A video showing how to edge and finish lenses with a lens finishing system in the office. It visually showcases processes such as lens edging, beveling, and polishing for optical labs.

Here’s how these systems work:

- Lens Insertion: The raw lens is securely positioned in the lens edger, ensuring proper alignment for accurate processing.

- Edging: The manufacturer shapes the lens to fit the frame perfectly, whether it is modern or classic.

- Beveling: Edges are smoothed and shaped for durability and compatibility with various frame styles.

- Polishing: Any imperfections are removed, resulting in crystal-clear lenses that enhance optical clarity.

- For rimless or semi-rimless designs, precise drilling secures the lenses and keeps them stylishly lightweight.

Each of these steps works harmoniously to create lenses that exceed patient expectations in quality and design.

How Automation Has Revolutionized Lens Finishing

Automation changes lens finishing systems into essential tools for optical labs. It provides speed, precision, and efficiency to meet today’s needs.

- Reduced Manual Intervention: Automation takes over repetitive tasks, freeing technicians to focus on patients and more complex priorities. This shift reduces human error and guarantees that every lens meets exact specifications.

- Unmatched Precision: Advanced systems handle edging, polishing, and beveling with exceptional accuracy. Labs processing high volumes can count on consistent, high-quality results across every lens.

- Increased Productivity: Automated systems significantly reduce production times by processing multiple lenses simultaneously.

Lens finishing systems integrate advanced automation to deliver measurable benefits: more efficient workflows, fewer errors, and happier patients. With these tools, your lab gains the precision, speed, and trust needed to thrive in today’s competitive optical landscape.

How Lens Finishing Systems Drive Precision, Efficiency, Trust — and ROI

Lens finishing systems redefine operational excellence for optical labs. Here’s how they add measurable value to your practice.

Optimizing Workflow and Productivity

Modern lens finishing systems combine key processes like edging, polishing, and beveling into a single automated unit. This integration removes bottlenecks and improves overall workflow control.

- Faster Turnaround Times: Meet tight deadlines with efficient lens processing that enables same-day or next-day service.

- Resource Efficiency: Free up staff to focus on patient care by automating repetitive tasks.

ROI Impact: In-office systems save $5 to $15 per lens, significantly lowering operational costs while boosting productivity.

Reducing Errors for Consistent Quality

Automation eliminates manual inconsistencies, ensuring every lens is crafted precisely and consistently.

- Fewer Defects: High-precision tools help reduce defect rates to less than 0.5%, lowering material waste and saving time.

- Reliable Results: Deliver consistently flawless lenses that reinforce your lab’s reputation for quality.

ROI Impact: Fewer remakes translate to significant annual savings and enhanced credibility.

Building Patient Trust and Retention

Patients expect their lenses to be high-quality and delivered on time. Meeting those expectations with speed and precision builds loyalty and trust.

- Satisfied Patients Return: Quick service and excellent results keep patients coming back.

- Expanded Referrals: Happy patients are more likely to recommend your practice to others.

ROI Impact: Data shows that 71% of patients will recommend providers when satisfied, boosting patient retention and referral rates.

Long-Term Returns on Investment

Investing in high-quality optical finishing equipment is a strategy for long-term profitability. These systems grow with your practice, offering enduring value.

- Built for Sustainability: Reliable construction minimizes repair needs and downtime, ensuring consistent performance over the years.

- Future Growth: Accommodate increasing patient demands without sacrificing efficiency or precision, positioning your lab for scalable success.

ROI Impact: Over time, these systems pay for themselves. They lower maintenance costs, increase output, and improve patient retention, making them essential for successful labs.

Top 5 Lens Finishing Systems to Boost Precision and Efficiency

Modern lens finishing systems solve the special problems that optical labs face. They help improve workflow efficiency and achieve great precision. Here are our five standout systems.

1. Briot Emotion 2 ($5,999.00)

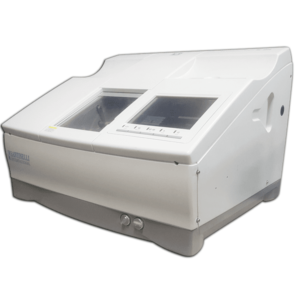

The Briot Emotion 2 is a small, all-in-one lens finishing system. It serves the precision and efficiency needs of small labs. Its standout features include:

- Compact Design: Fits seamlessly into small spaces without sacrificing performance.

- All-in-One Functionality: Combines edging and polishing in a single machine to simplify workflows.

- Ease of Use: Features an intuitive interface that makes operations quick and easy, reducing the chance of errors.

- Reliable Build: Built for long-term durability to ensure consistent, high-quality results.

- Enhanced Productivity: Advanced automation speeds up processes, helping labs meet tight deadlines with confidence.

This system is a top choice for optical professionals seeking dependable optical finishing equipment that improves efficiency and delivers exceptional results.

2. Briot Perception 2 ($6,025.00)

The Briot Perception 2 is a compact, patternless lens finishing system for small- to medium-sized labs. It offers:

- Patternless Design: Eliminates the need for traditional patterns, saving time and reducing material waste.

- Compact Footprint: Fits into smaller spaces without compromising performance, making it ideal for labs with limited workspaces.

- Automated Lens Finishing: Automates critical tasks like edging and polishing, ensuring precision and consistency with every lens.

- User-Friendly Interface: The intuitive control panel simplifies operations for technicians of all experience levels.

- Efficiency Boost: It speeds up workflows and reduces manual labor, helping labs deliver quicker turnaround times and higher productivity.

The Briot Perception 2 is a reliable choice for labs looking to integrate optical finishing equipment that prioritizes efficiency, precision, and space optimization.

3. Visionix Briot Attitude 3 ($3,999.00)

The Visionix Briot Attitude 3 is a powerful lens edger for optical professionals. Designers create it for complex and advanced lens styles. Its standout features include:

- Advanced Beveling Technology precisely shapes lens edges, ensuring a perfect fit for even unique frame designs.

- Cutting-Edge Precision: This handles intricate cuts with exceptional accuracy, ideal for labs specializing in custom or high-end eyewear.

- High-Speed Performance: Boosts productivity by processing lenses quickly without compromising on quality.

- User-Centric Controls: An Intuitive interface simplifies complex tasks, streamlining workflows.

This system is perfect for labs demanding precision, efficiency, and advanced functionality in their optical finishing equipment.

4. Essilor ES 800

The Essilor ES 800 is a durable and dependable lens finishing system, ideal for labs managing high production volumes. Key features include:

- Built for Durability: Engineered for long-term reliability, even in demanding, high-output environments.

- Automated Lens Finishing: Integrates advanced automation to streamline processes like edging and polishing, ensuring consistent, high-quality results.

- High-Volume Performance: Handles large workloads efficiently, reducing production times without compromising accuracy.

- Intuitive Operation: Simplifies workflows with user-friendly controls, minimizing learning curves for technicians.

The designers created the Essilor ES 800 for efficiency and reliability. A trusted choice for labs that want productivity and accuracy in optical lab equipment exists.

5. Santinelli Nidek ME 1000 ($6,666.00)

The Santinelli Nidek ME 1000 is an excellent lens finishing system. Its design targets labs that specialize in custom, high-quality eyewear.

Key features include:

- Advanced Drilling Capabilities: Ensures precision for rimless and semi-rimless frame designs, delivering flawless results.

- Customizable Options: Adapts to unique lens requirements, making it perfect for bespoke and intricate designs.

- High-Quality Finishing: Handles delicate and complex processes with exceptional care and accuracy.

- User-friendly interface: Simplifies customization, enabling technicians to achieve precise results efficiently.

This system is necessary for professionals seeking premium optical finishing equipment to produce unique, high-quality lenses.

Tips for Selecting and Maintaining Lens Finishing Systems

Choosing and maintaining the right lens finishing system ensures precision, efficiency, and profitability. Here’s how:

Selection Tips

Consider your lab’s specific requirements and operational goals:

- Assess Production Needs: Small labs do well with compact, multi-functional systems. High-volume labs require strong equipment with more capacity.

- Prioritize Automation and ROI: Automation minimizes errors and speeds up workflows, offering measurable savings and long-term efficiency.

- Look for Easy-to-Use Features: Systems with simple controls reduce training time, helping technicians focus on getting good results.

Maintenance Tips

Regular care and servicing maximize your system’s lifespan and performance:

- Routine Cleaning and Calibration: Keep dust and misalignments in check with regular maintenance to ensure precision and accuracy.

- Professional Servicing: Schedule preventative check-ups with qualified technicians to minimize downtime, prevent costly repairs, and maintain consistent quality.

By selecting the right equipment, your lab can save money. Keeping the equipment in good condition can improve efficiency and improve patient results.

Elevate Your Optical Lab with Shape Ophthalmics’ Lens Finishing Solutions

Running a successful optical lab involves more than just making lenses. It also consists in meeting patient needs while being efficient and profitable. Lens finishing systems transform daily operations, making precision and reliability second nature.

Key Takeaways:

- Save time and cut costs by streamlining workflows.

- Deliver flawless, high-quality lenses your patients can trust.

- Build patient loyalty with faster, consistent service.

With advanced technology and unmatched expertise, Shape Ophthalmics delivers solutions that elevate your lab’s potential. We commit to innovation and customer care to equip you for success.

Discover the right lens finishing system for your lab.

Explore Shape Ophthalmics’ advanced product line today and take the next step toward precision, efficiency, and growth.