As optometry clinics look to maximize profits and provide the highest level of patient care, modern lens edger technology can be a great asset. Lens edgers are precision machines that cut and shape eyeglasses and sunglasses lenses.

With modern lens edger technology advancements, optometry clinics can increase efficiency, save time and money, and provide the best products for their patients. This blog post will examine the advantages of investing in modern lens edger technology and how it can help clinics improve their profit margins.

What Is a Lens Edger?

A lens edger is a machine used to shape a lens’s edges. It is an important tool in any optical shop or clinic, ensuring the lenses have smooth edges and an even fit. Lens edgers use technology such as water jets, air jets, sanding belts, and polishing wheels to shape and finish the edges of lenses.

Lens edgers are essential for anyone who works with lenses, as they ensure they fit comfortably in frames and look good on patients. In addition, lens edgers make cutting lenses simpler and faster. They also help reduce the risk of errors and waste since they can shape the lenses precisely as required without manual trimming or grinding.

Lens edgers can shape any lens, from simple single-vision to complex progressive lenses. They are also suitable for shaping glass lenses and plastic ones. In addition, the lens edger can be programmed to create specific shapes and sizes to get the exact fit you need for each patient.

Using a lens edger helps to ensure that your lenses are free from imperfections. The machine can accurately shape the edges of lenses so that no gaps or cracks could cause discomfort or impede vision. This means that your patients will receive well-fitted lenses that are comfortable and effective.

By investing in modern lens edger technology, optometry clinics can save time and money by cutting lenses faster and more accurately. This will result in a higher quality product for the patient and a lower cost for the clinic, which can lead to increased profits. Additionally, the technology can reduce the number of mistakes and the risk of liability for the clinic.

What Does a Lens Edger Do?

A lens edger is a piece of machinery used in the optical industry to cut, shape, and polish lenses for eyeglasses. The process involves cutting the lens to the desired size and shape and polishing it to fit snugly into the glass’s frame.

- The machine uses a combination of wheels, belts, and polishing pads to produce a precise finished product.

- The lens edger works by first loading the uncut lens onto the machine.

- The lens is firmly placed while a computer-controlled motor operates the grinding and polishing components.

- During this process, the motor will turn the grinding wheels and belts at different speeds to produce a consistent finish on the lens.

- The edger will also use varying pressure to ensure perfectly smooth lens edges.

- Once the lens edges have been shaped and polished, the machine will move to the final stage of the process. This involves using a polishing pad to give the edges of the lens an attractive shine.

- Once complete, the lens is ready for fitting into frames.

Lens edgers are essential for opticians, allowing them to create custom-fitted lenses for each customer. As a result, opticians can use a lens edger to provide their customers with perfectly fitting eyeglasses that offer optimal vision and comfort.

The Different Types of Lens Edgers

Lens edgers are machines used to cut lenses to the shape of a patient’s frames. There are three main types of lens edgers:

- Manual

- Automatic

- Semi-automatic

Manual lens edgers are the most basic type. They require an operator to adjust the cutting tool manually and cut the lens according to the frame shape. This type of lens edger is often slower and more labor-intensive than other types.

Automatic lens edgers are much faster and more precise than manual models. These machines use a computer-controlled system that adjusts the cutting tool to match the frame’s shape. This makes them ideal for larger clinics that need to produce high volumes of lenses quickly and accurately.

Semi-automatic lens edgers are a combination of manual and automatic edgers. They still require an operator to adjust the cutting tool, but they also use a computer-controlled system to guide the movement of the cutting tool. This makes them great for smaller clinics that don’t need the speed and precision of an automatic machine but still want to be able to produce accurate results.

The Benefits of a Lens Edger

A lens edger is a must-have for any clinic that wants to stay competitive in today’s marketplace. This specialized technology is designed to streamline producing and delivering high-quality eyeglasses while helping clinics maximize profits. With a lens edger, you can get the job done quickly and efficiently, and some of the top benefits include the following:

- Increased Efficiency: Lens edgers can help you produce eyeglasses faster, with less time and effort spent on manual labor. This means you’ll be able to process orders faster and get them out the door faster.

- Lower Costs: When you produce eyeglasses with a lens edger, you don’t have to pay for additional labor costs associated with manual production. This can help your clinic save money and increase its profit margin.

- Higher Quality Products: A lens edger ensures that each pair of eyeglasses is accurately produced. This means you’ll be able to provide your customers with the highest quality products at an affordable price.

- More Convenient Production: With a lens edger, you can produce eyeglasses without using traditional methods like hand grinding and polishing. This makes production simpler and more convenient.

- Reduced Errors: A lens edger reduces the chances of errors during manual production, such as incorrect measurements or cutting. This helps to ensure that each pair of eyeglasses is made perfectly.

- Automation: With a lens edger, you can automate the entire production process, which makes it easier and faster to complete orders. This eliminates the need for manual labor and improves efficiency.

The benefits of a lens edger are clear – this amazing technology can help your clinic increase efficiency, reduce costs, and provide your customers with the highest quality products. So if you’re looking to maximize your clinic’s profitability, investing in a lens edger is a great way to do it.

Is It Worth It to Buy Lens Edger As an Investment?

Absolutely! Investing in a lens edger is one of the best decisions you can make for your clinic. Not only can it help you save time and money, but it can also help you increase your profits in a variety of ways.

A lens edger is an automated machine that precisely cuts and shapes lenses to fit into frames. It’s an incredibly efficient way to create lenses since it takes only a few seconds to do what used to take hours. This efficiency increases productivity and decreases labor costs and allows you to complete more orders in less time and pass on the savings to your customers.

In addition, a lens edger can provide additional services, such as customizing lenses with unique shapes, that can help you stand out from the competition and attract more customers. All of these benefits combined make investing in a lens edger a great decision that can boost your profit margins.

What Is Abbe Value and How Is It Used?

Abbe value is an important measurement in optics that indicates the chromatic dispersion of a lens. It helps to determine the quality of a lens and how well it can disperse light into its various colors. This is important for determining how well a lens can provide clear, crisp vision.

The Abbe value measures how well a lens can refract light into its different colors. It is calculated by measuring the refractive index of the material that the lens is made of. The higher the Abbe value, the less dispersion of light occurs, resulting in better clarity of vision. Therefore, an Abbe value is an important factor in determining the quality of a lens.

Abbe value is also related to the lens edger because the edger will help to shape and cut the lenses based on this value. The higher the Abbe value, the better the clarity of vision the lens will provide.

What Criteria Does a Lens Edger Need to Meet?

Some criteria your lens edger should meet include the following:

- It needs to provide the best possible care for your patients. This includes offering a wide range of lens options and accurate cutting and grinding services.

- It needs to meet patients’ desires for convenience. By purchasing an edger, you can profit from the patients’ demand for immediate satisfaction.

- It needs to handle different types of lenses, such as single-vision, bifocal, and progressive lenses.

- It helps you compete with optical retailers. Many patients are looking for the convenience of purchasing their lenses from where they get their eye exams and frames.

- It needs to be reliable and efficient. You don’t want an edger that takes too long or breaks down frequently.

- It needs to save and make you money. Investing in a quality lens edger will reduce the time spent grinding and polishing each lens, allowing you to see more patients in less time.

- It needs to be up-to-date with the latest technology and software. The latest lens edgers feature advanced algorithms that can quickly and accurately grind and polish various lenses with minimal operator intervention.

Best Optical Lens Edger Machines for Optometrists in 2023

When selecting a lens edger machine, optometrists should consider factors such as processing speed, precision, versatility, ease of use, maintenance requirements, and cost. Some popular brands and models that meet these criteria include:

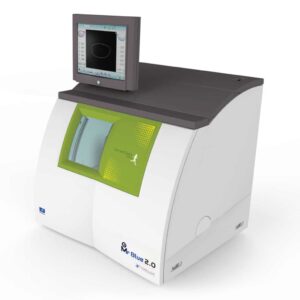

1. Essilor Mr. Blue 2.0 ($7,555.00)

Mr. Blue 2.0 by Essilor Increase revenue by providing an alternative to prescription Sunwear and unsatisfactory clip-on sets. It features a magnetic lens layering system with a base curve matched, lightweight, custom-made frame.

Mr. Blue 2.0 by Essilor advantages:

- Adapted to all types of fittings thanks to “Fit 4 Frame” technology

- High-precision fittings

- Securing of fittings for superhydrophobic lenses thanks to milling

- Easy to clean and maintain the tray –

- Very aesthetic and ideal to be installed in the center of the point of sale

2. Briot Couture ($9,999.00)

With its lens edging, drilling, and grooving capabilities, intuitive software, and customizable settings, the Briot Couture Lens Finishing System provides a comprehensive solution for eyewear manufacturing.

The Briot Couture Lens Finishing System provides several advantages for eyewear professionals. Here are some of its key advantages:

- Precision: The Briot Couture Lens Finishing System utilizes advanced technology to provide precise lens finishing, resulting in accurate prescriptions and optimal patient vision.

- Efficiency: The Briot Couture Lens Finishing System allows quick and easy adjustments to meet specific patient needs, streamlining the eyewear manufacturing process and improving practice efficiency.

- Versatility: With its lens edging, drilling, and grooving capabilities, the Briot Couture Lens Finishing System offers a comprehensive solution for eyewear manufacturing, making it an essential tool for optometrists, opticians, and other eyewear professionals.

- User-friendly design: The Briot Couture Lens Finishing System features intuitive software and customizable settings, making it easy to operate and adjust according to specific practice needs.

3. Briot Emotion 2 ($7,999.00)

The Briot Emotion 2 All-in-one Lens Finishing Lab provides several advantages and benefits for eyewear professionals. Here are some of its key advantages:

- Precision: The Briot Emotion 2 All-in-one Lens Finishing Lab utilizes advanced technology to provide high-precision lens finishing, resulting in accurate prescriptions and optimal patient vision.

- Efficiency: With its lens edging, drilling, grooving, and tracing capabilities, the Briot Emotion 2 All-in-one Lens Finishing Lab offers a comprehensive solution for eyewear manufacturing, streamlining the process and improving practice efficiency.

- Versatility: The Briot Emotion 2 All-in-one Lens Finishing Lab is a versatile tool that can perform multiple functions in one compact unit, making it an essential device for optometrists, opticians, and other eyewear professionals.

- User-friendly design: The Briot Emotion 2 All-in-one Lens Finishing Lab features intuitive software and customizable settings, making it easy to operate and adjust according to specific practice needs.

- Cost-effective: By combining multiple functions in one unit, the Briot Emotion 2 All-in-one Lens Finishing Lab can save on equipment costs and space in practice.

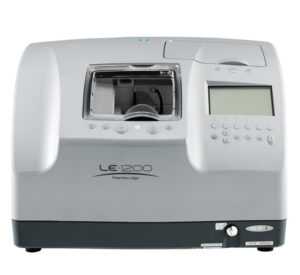

4. Nidek LE 1200 Patternless Lens Edger ($4,500.00)

The Nidek LE 1200 Patternless Lens Edger offers a variety of advantages and benefits to ophthalmic laboratories and eyewear professionals. Some of these advantages include the following:

- Faster and more efficient edging: The LE 1200 does not require a pattern or tracing, which means it can edge lenses faster and more efficiently than traditional edging machines. This can help to increase productivity and reduce turnaround times for eyeglasses.

- Precision and accuracy: The advanced technology used by the LE 1200 allows for precise and accurate cutting of lenses, ensuring a high-quality finished product. This can lead to greater patient satisfaction and improved outcomes.

- Compatibility with a wide range of materials: The LE 1200 can edge various lens materials, including high-index lenses, polycarbonate, and Trivex. This makes it a versatile tool for any eyewear lab.

- Customization options: The device includes a built-in drill and grooving feature, creating customized frames for progressive lenses. This can help meet individual patients’ unique needs and improve overall satisfaction.

- Safety features: The LE 1200 includes a safety beveling feature that helps prevent the lenses from chipping or cracking during edging. This can help to reduce waste and save time and money on re-edging.

- Compact and ergonomic design: The LE 1200 is compact and ergonomic, making it easy to operate and ideal for smaller lab spaces. This can help to optimize the use of space in a lab and improve overall efficiency.

Overall, the Nidek LE 1200 Patternless Lens Edger offers numerous benefits and advantages to ophthalmic laboratories and eyewear professionals. Its advanced technology, versatility, and safety features make it an es

5. Briot Perception 2 ($7,999.00)

Here are some advantages or benefits of using Briot Perception 2:

- Precision: The Briot Perception 2 utilizes advanced digital technology to perform a 3D scan of the lens, providing accurate data about its curvature, thickness, and other important measurements. This results in precise lens edging and improved visual performance for the wearer.

- Efficiency: The machine’s automated blocker system simplifies and speeds up the lens edging process, allowing for faster production times and increased efficiency in optical labs.

- Customization: The Briot Perception 2 is equipped with a range of polishing and finishing tools, which allow for a range of lens customization options, including progressive, single vision, and specialized lenses.

- Ease of use: The machine’s intuitive user interface, large color touchscreen, and user-friendly software system make programming and operation easy.

- Quality: The Briot Perception 2 is designed to create high-quality ophthalmic lenses, resulting in an improved visual performance for the wearer and increased satisfaction for eye care professionals.

- Cost-effective: The machine’s precision and efficiency reduce waste and increase productivity, leading to cost savings for optical labs and eye care professionals.

Overall, the Briot Perception 2 offers a range of benefits and advantages that make it a valuable tool for optical labs and eye care professionals looking to improve the quality and efficiency of their lens production.

Conclusion

Investing in modern lens edger technology can help clinics maximize their profit potential. The right lens edger can provide a high-quality, cost-effective solution to common lens processing issues and increase patient satisfaction.

Optometry clinics can boost their profits by selecting the most advanced lens edger technology. At Shape Ophthalmics, we recognize that each practice has unique ophthalmological lens edger requirements.

By understanding the different types of lens edgers and what criteria they need to meet, clinics can decide which one is best suited for their practice. In addition, understanding the basics of using a lens edger properly can ensure that the investment pays off in the long run. Finally, investing in modern lens edger technology is a great way to maximize your clinic’s profitability.